Welding standard specification and process

Release Time:

Jun 07,2024

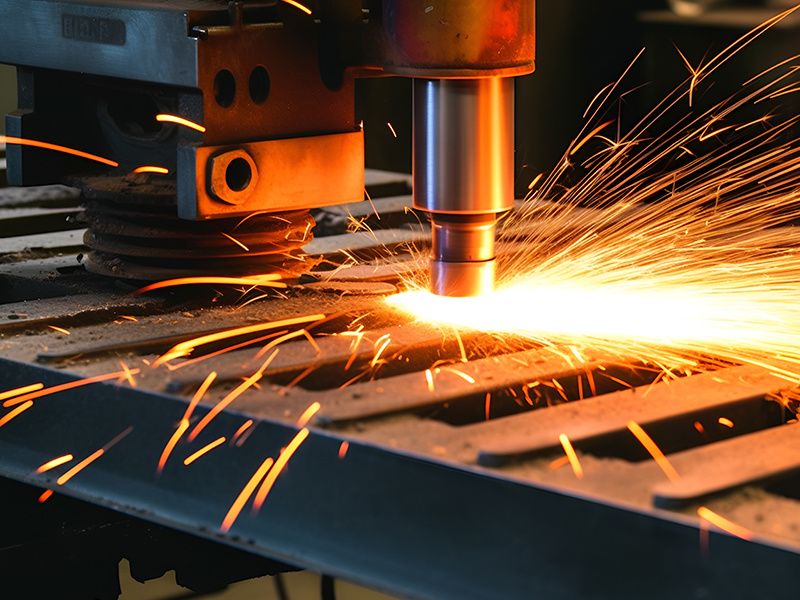

Welding standards and processes are important guarantees to ensure the welding quality during the production and installation of steel structures. The following is a summary of the relevant pages:

Welding standards and processes are important guarantees to ensure the welding quality during the production and installation of steel structures. The following is a summary of the relevant pages:

Scope of application: The standard specifications of welding engineering are usually applicable to the manual arc welding of steel structures in general industrial and civil construction projects.

Preparation for construction:

Materials and main tools: including welding rods, the model should be selected according to the design requirements.

The external wiring of the welding equipment must be firm and reliable, especially the return route of the workpiece.

Key points of welding process:

Select appropriate welding auxiliary devices, such as welding machines and their auxiliary equipment, circuits, waterways, gas routes and mechanical devices should ensure normal.

Before welding, the surface of the body parts should be cleaned to remove dust, oil, paint, oxide, rust, etc.

To monitor the correctness of welding process specification, peeling test or picking test of welding workpiece with flat shovel is carried out.

In the implementation of welding engineering, compliance with the above standard specifications and process requirements is essential to ensure welding quality and safety.

What Else Might You Learn?